Description

Here are some tips on how to build a cold room.

Recommended insulation is at least 10 cm with insulation in walls ceilings and floors. Moisture barrier should always be on the hot side of the insulation. Here, plastic foil is used as a moisture barrier with a thickness of 0.15-0.25 mm, all joints are overlapped and taped.

No diffusion-proof materials must be found inside the cold room. The recommended wood type inside the cold room is spruce. If you want and surface treat the wood inside the cold room, it is and preferably a diffusion-open, water-based panel lacquer.

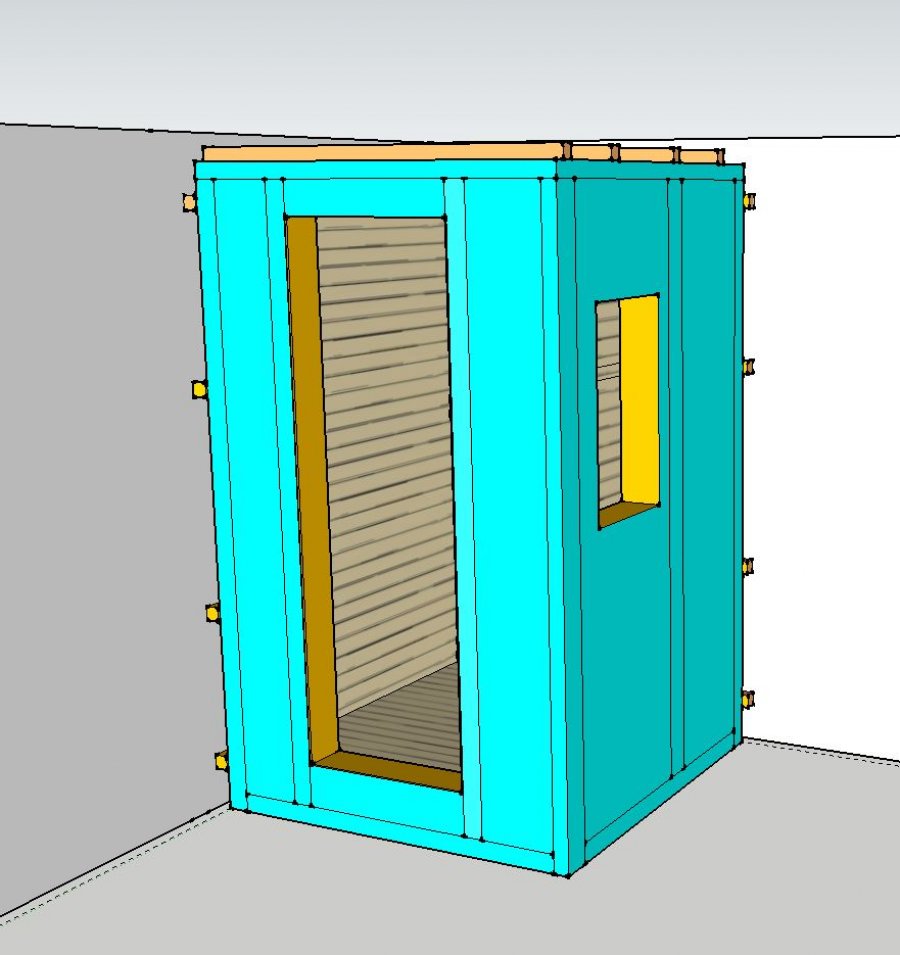

Cold attic or cold basement (below + 0 ° C in winter) ventilation must be made using blocks of 5 cm thickness. The plastic is attached to the bricks before the binder. Venting is done by means of slots in the moldings. In this way + degrees are ensured around the cold room throughout the year, and you will not have rot problems because of. condensation.

More information about building up can be found at Glava or at Byggebolig.no’s blog.Byggebolig.no

COLD ROOM DOORS:

Integrated cold room door is used if you want to install a furniture plate on the door leaf so that it is similar to the kitchen interior.

Surface cold room door is a little more affordable about most used door for self-built cold rooms. We can tailor cold room doors, if the standard door does not fit.

COOLING UNIT:

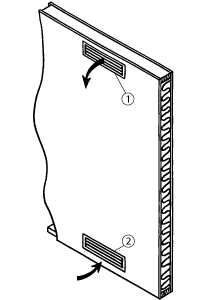

Also, no outside space is required for the cooling unit. It is inserted from inside the cold room. Air to and from the unit is passed through valves or one plastic cover. The only maintenance required is cleaning a dust filter, located in the front of the unit inside the cold room.

Split heater (two split cooling units) is also recommended. The compressor part is often placed in a laundry room or basement / technical room up to 10 meters away.

Thermocold cooling units are very compact, quiet and have the lowest power consumption on the market. It provides the right temperature and humidity. Normal product temperatures are approx. to 5 ° C. The temperature in the air around the room varies e.g. between 2.5 to 7 ° C. Therefore, it is important to measure the temperature with a thermometer placed in a glass of water. In this way, the temperature is measured.

LIGHTS IN THE COLD ROOM:

Thermocold cooling units have a connection for light mounted in the ceiling, the power is obtained via a contact on the unit.

WINE BASEMENTS AND COLD ROOMS IN ONE:

By dividing the cold room into two with a 5 cm insulated wall and adjustable shelf up and down, you will get a cold room of 5 ° C and a wine cellar of 12-13 ° C.

In this way you get a practical refrigerator / cool room with the same cooling unit.